Binmaster designs and manufactures reliable solid state point and continuous bin level indicators control systems and sensoring devices used while storing powders and bulk solids.

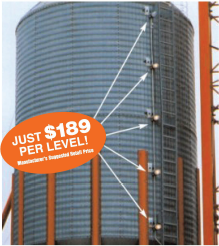

Bin level sensor price.

Reliable and precise in high dust 80 ghz non contact radar excels in powders and solids in tall and narrow vessels.

Reliable and cost effective bin level indicators inventory monitors and level sensor accessory devices suitable for use with powder granular liquid and slurry materials in a wide range of industries including those within the concrete grain plastic and process industries such as seed feed grain concrete cement sand gravel asphalt chemical processing pla.

Sensoneo s solution is a result of in house r d.

We design develop and produce the sensors and all software in.

A laser level measurement sensor is used for level control plugged chute detection and monitoring buildup.

Avoid the collection of overfilled or half empty trash bins.

The binmaster ncr 80 is a non contact radar level sensor designed for superior performance in extremely dusty powders and bulk solids.

The company is a subsidiary of garner industries a custom manufacturer of plastic and metal parts.

This dramatically increases the accuracy of the sensor as it provides multiple reference points rendering false positives a thing of the past.

This non contact device measures in a tight beam making it suitable for use in very narrow vessels constrained spaces or in applications where the beam must be precisely targeted to avoid walls or other structures.

Our optical sensor is equipped with a 256 pixel resolution that enables it to produce 3d depth maps of a bin s content.

Non contact radar continuously measures the level of powders granules solids or liquids in a vessel.

Its powerful 80 ghz frequency focused in a narrow 4 beam angle with a measuring range up to 393 feet and accuracy within 0 2 inches means it excels in tall and narrow vessels.

Binmaster manufactures technologies for level measurement and inventory management for process industries monitoring bulk solids powders and liquids.

Depending upon the unit s design powder level sensors use either a mechanical paddle or electrical capacitance trigger to determine and help control the level and flow of powdered material in a storage tank or in a pipeline.

Established in 1953 garner industries is certified to iso 9001 quality management systems requirements.

.jpg)